Thermal Imaging Services

Prevent fires, equipment failures, and costly repairs with a thermographic inspection

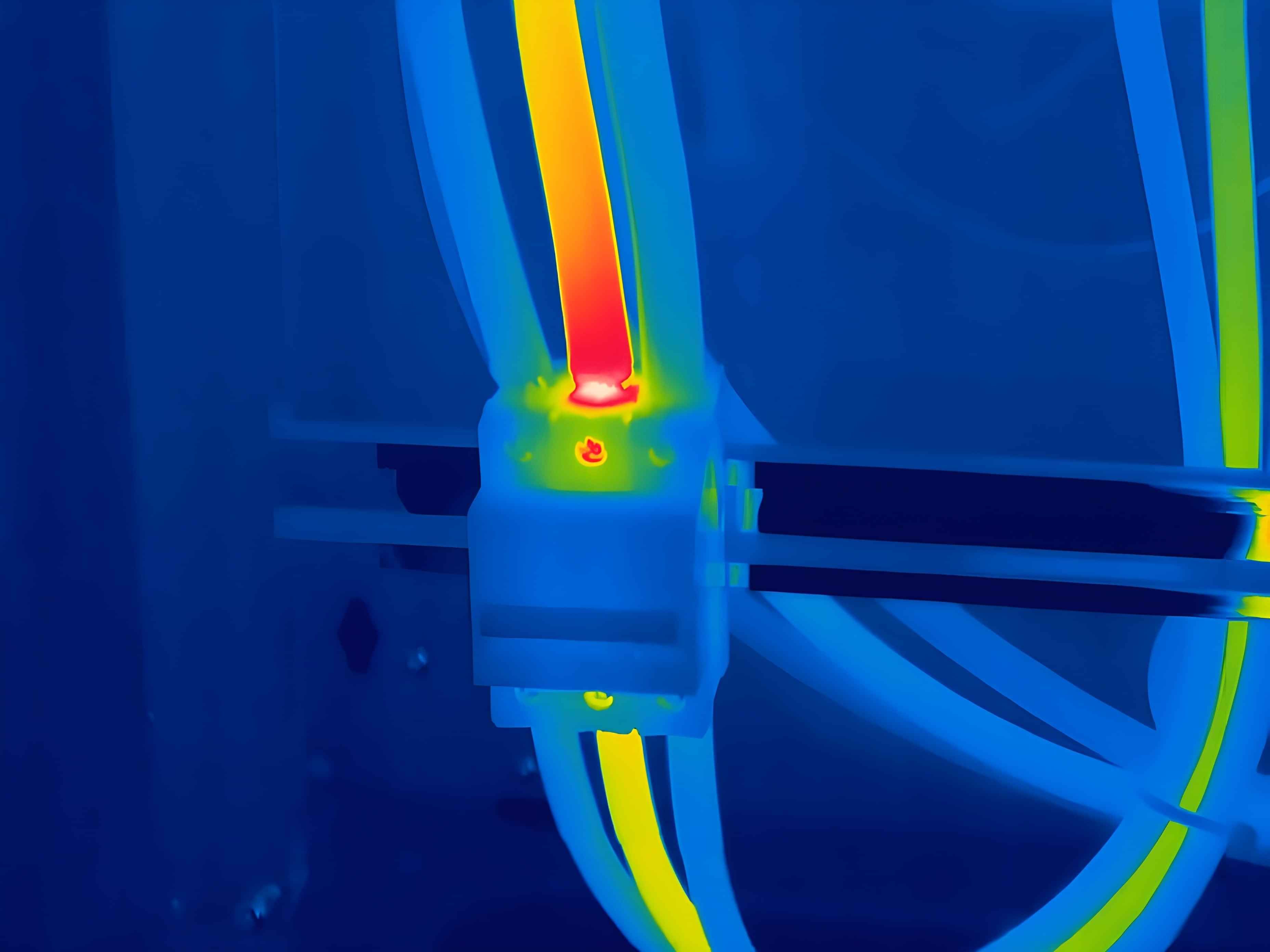

Electrical Thermography

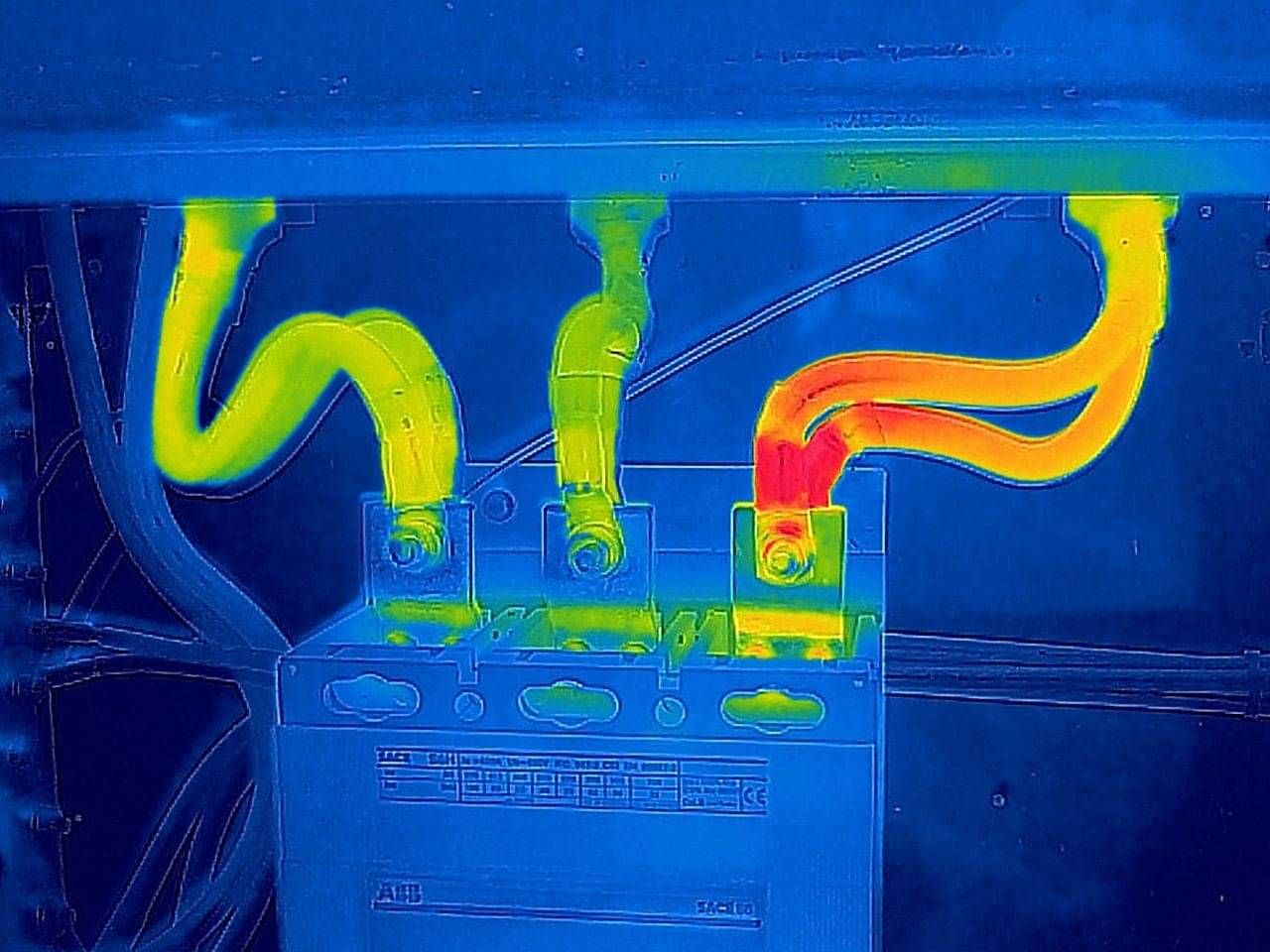

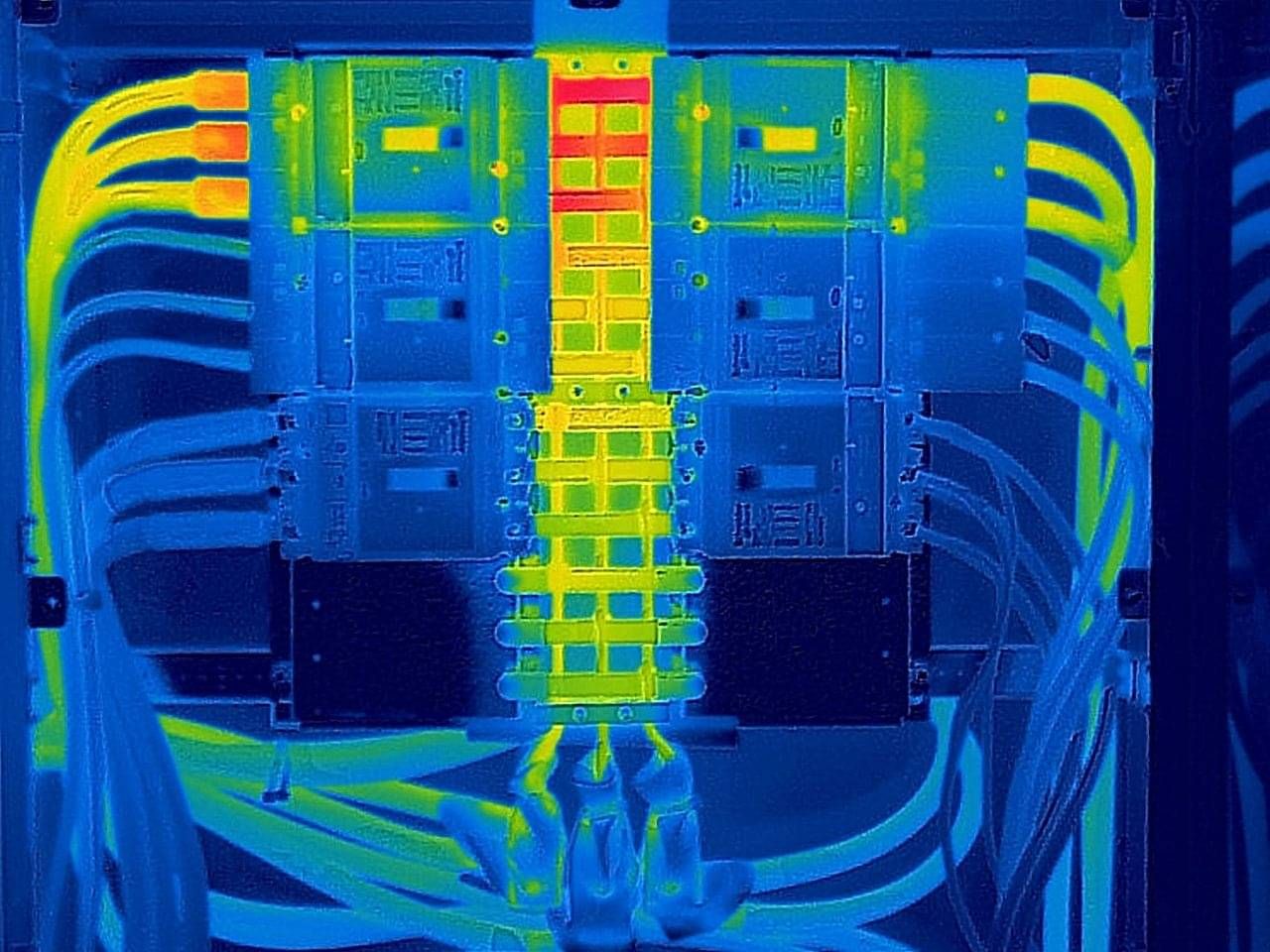

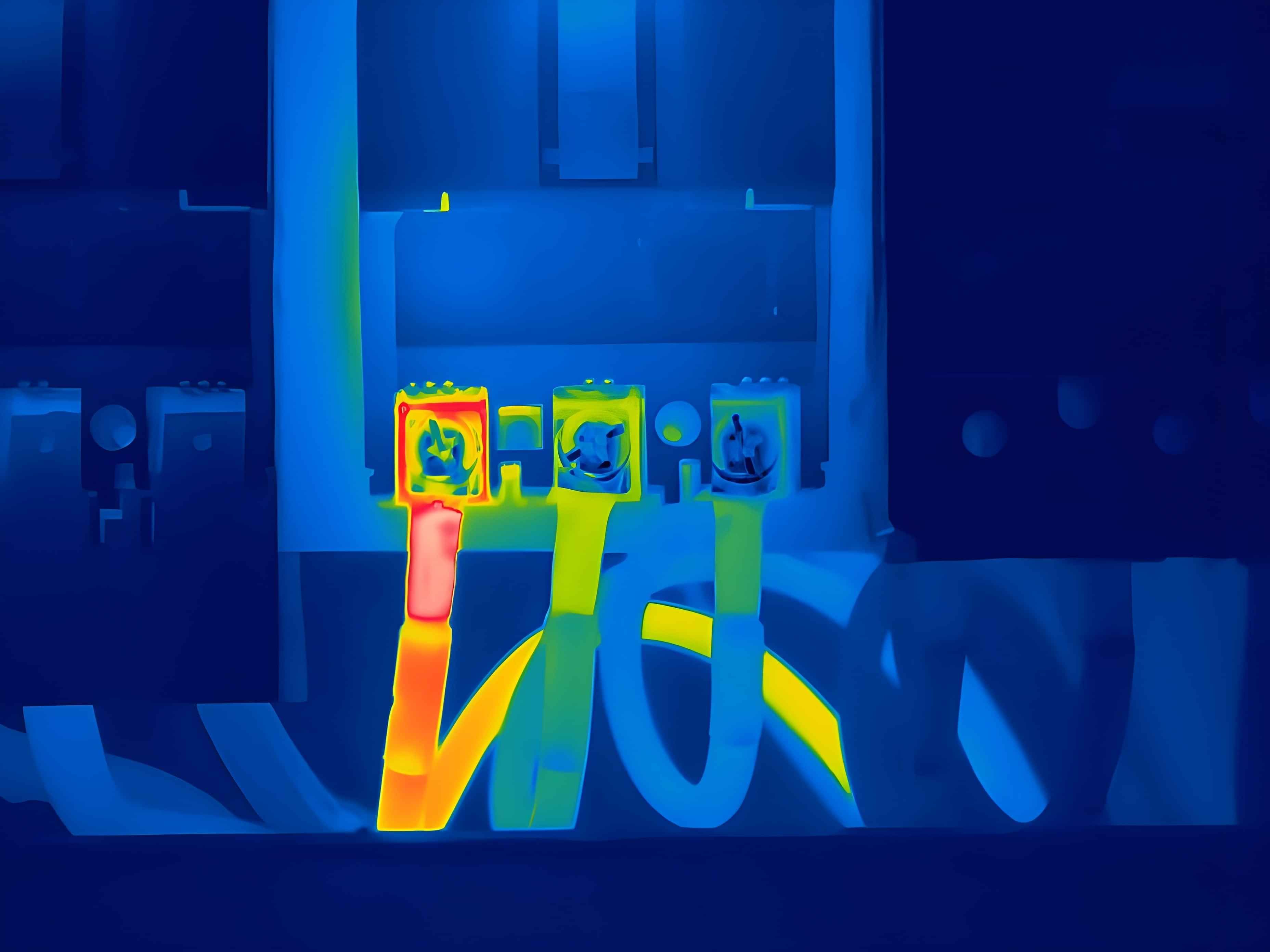

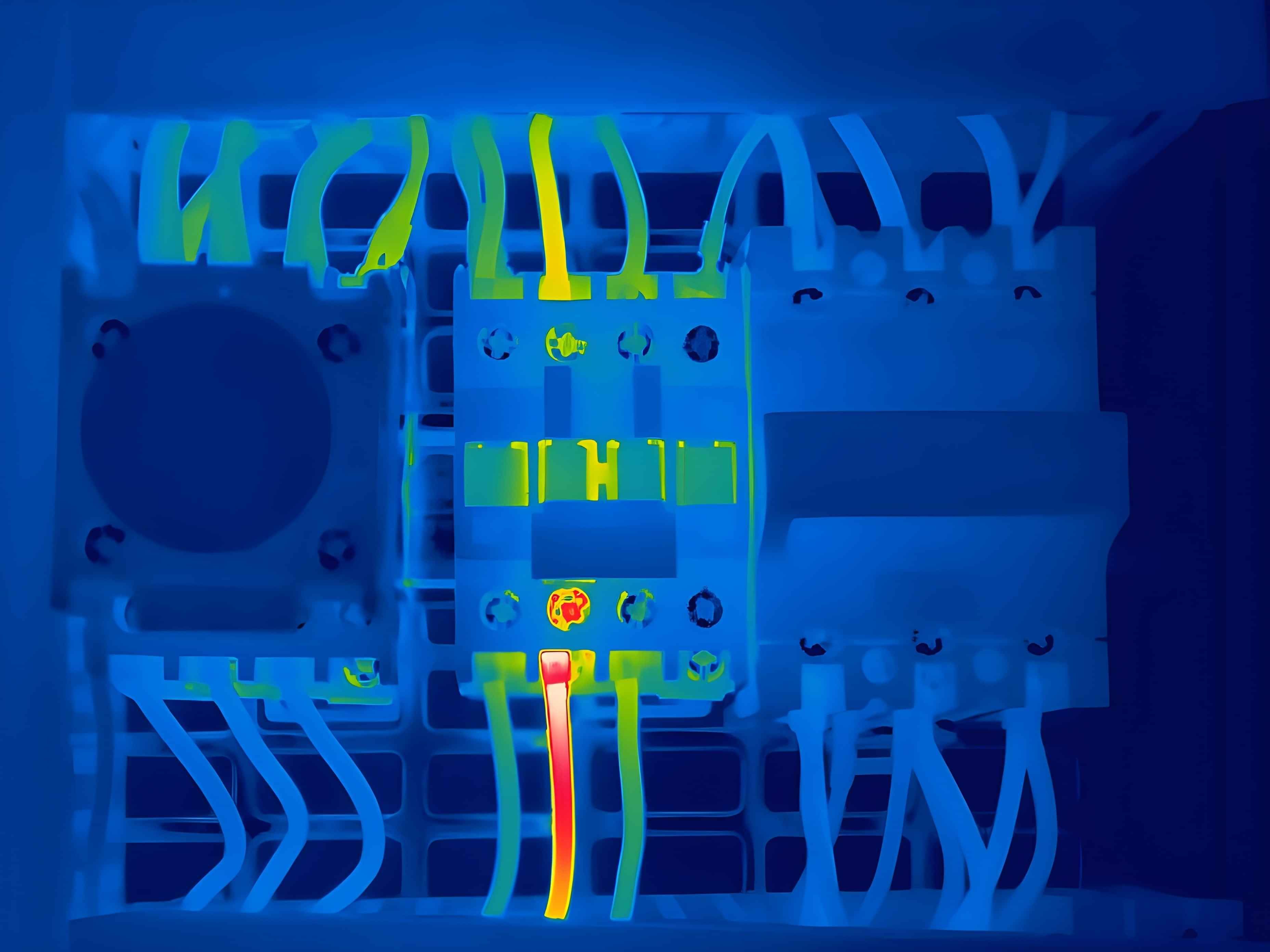

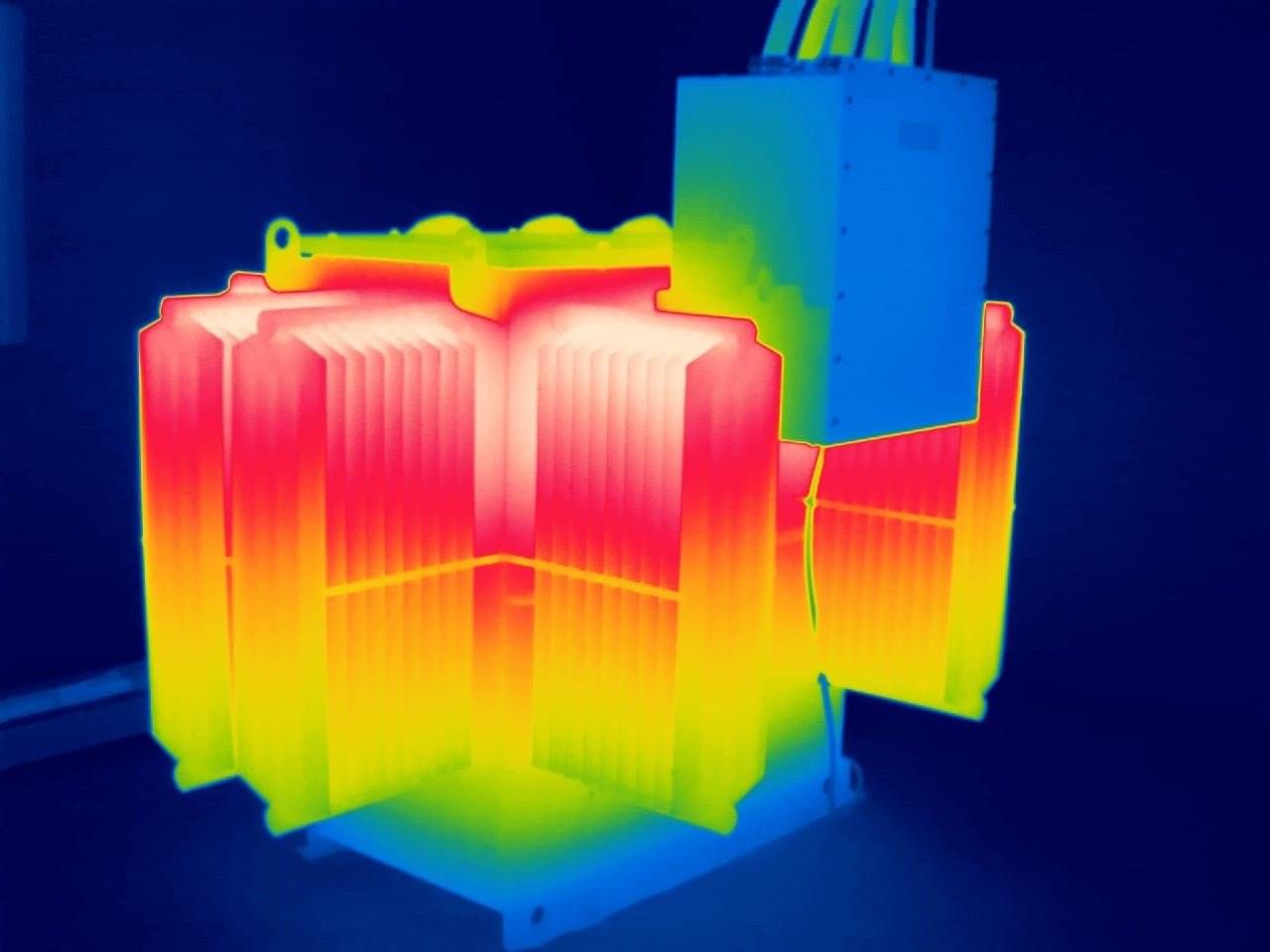

Each year in New Zealand, more than 1,500 fires are linked to electrical equipment. Our electrical thermal imaging inspections can identify overheating components and other early warning signs before they become serious problems. By detecting faults early, we help you reduce the risk of fire, equipment failure, unplanned downtime, and costly repairs. Our detailed reports offer peace of mind, and they keep your insurer satisfied too.

Electrical items we inspect include:

Switchboards, control cabinets, wiring, metering, distribution systems, PFC units

UPS battery back up systems, PV solar arrays, DC systems, generators

Motors, drives, starters, power supplies, harmonic filters

Lighting, sockets, switches, underfloor heating, appliances, chargers

High voltage transformers, transmission lines, switchgear, ripple systems

Common issues we detect include:

Loose connections, poor terminations, corroded contact surfaces, insulation failures

Overheating components such as circuit breakers, fuses, isolators, contactors etc

Faulty cables, joints, and switchgear

Load imbalances in multi phase systems

High resistance components

Excessive heat in cable looms, trunking, and cable management systems

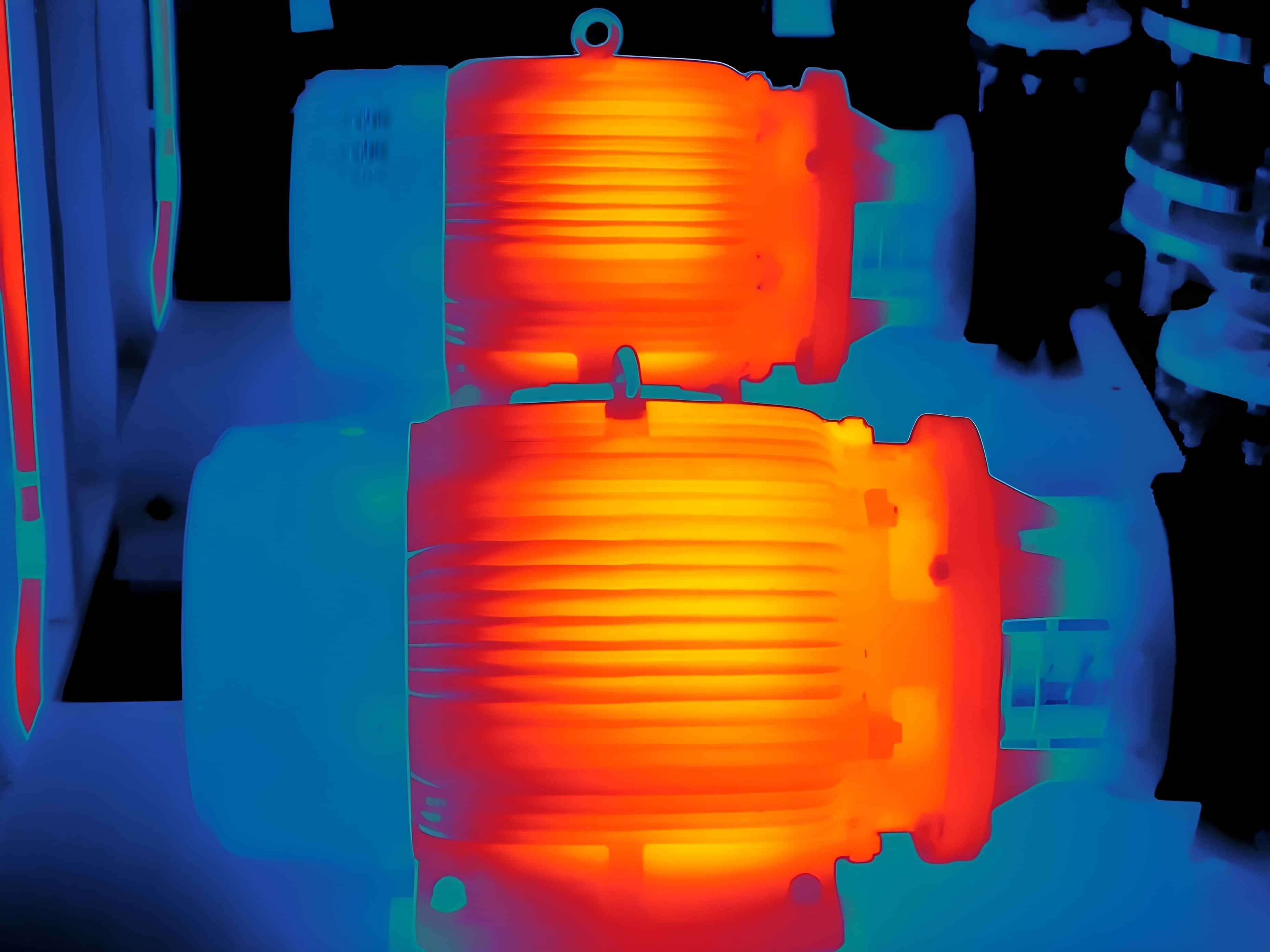

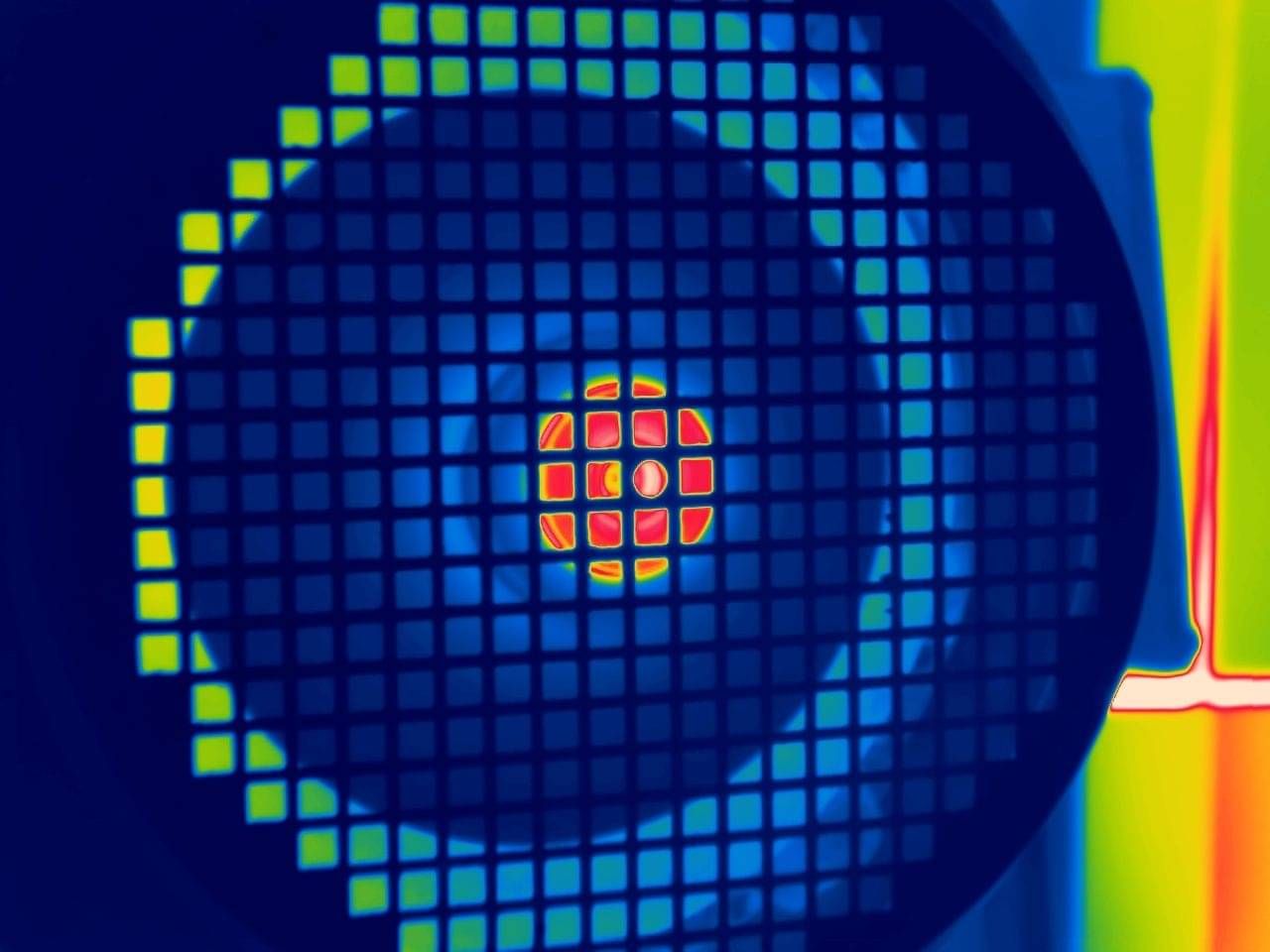

Mechanical Thermography

Mechanical equipment is essential across various industries. Businesses rely on machinery to create their products, automate processes, reduce labour costs, and maintain high output levels. As part of your preventative maintenance or condition monitoring plan, investing in regular mechanical thermal imaging inspections can extend the reliability and life span of machinery, minimize unplanned downtime, and prevent costly repairs or replacements.

Mechanical items we inspect include:

All types of production, manufacturing, and process machinery

Conveyors, motors, drive systems, elevators, pumps, palletisers, formers, mixers, fillers, crushers, ovens, hydraulic systems, winches, cranes, robots etc

HVAC units, extraction systems, heat exchangers, compressed air systems, boilers

Common issues we detect include:

Excessive friction due to worn bearings, poor lubrication, components touching etc

Misaligned components - shafts, drive belts, gear sets, motors, rollers etc

Fluid blockages, fluid and gas leaks, poor ventilation

Material degradation, delamination, corrosion, contamination

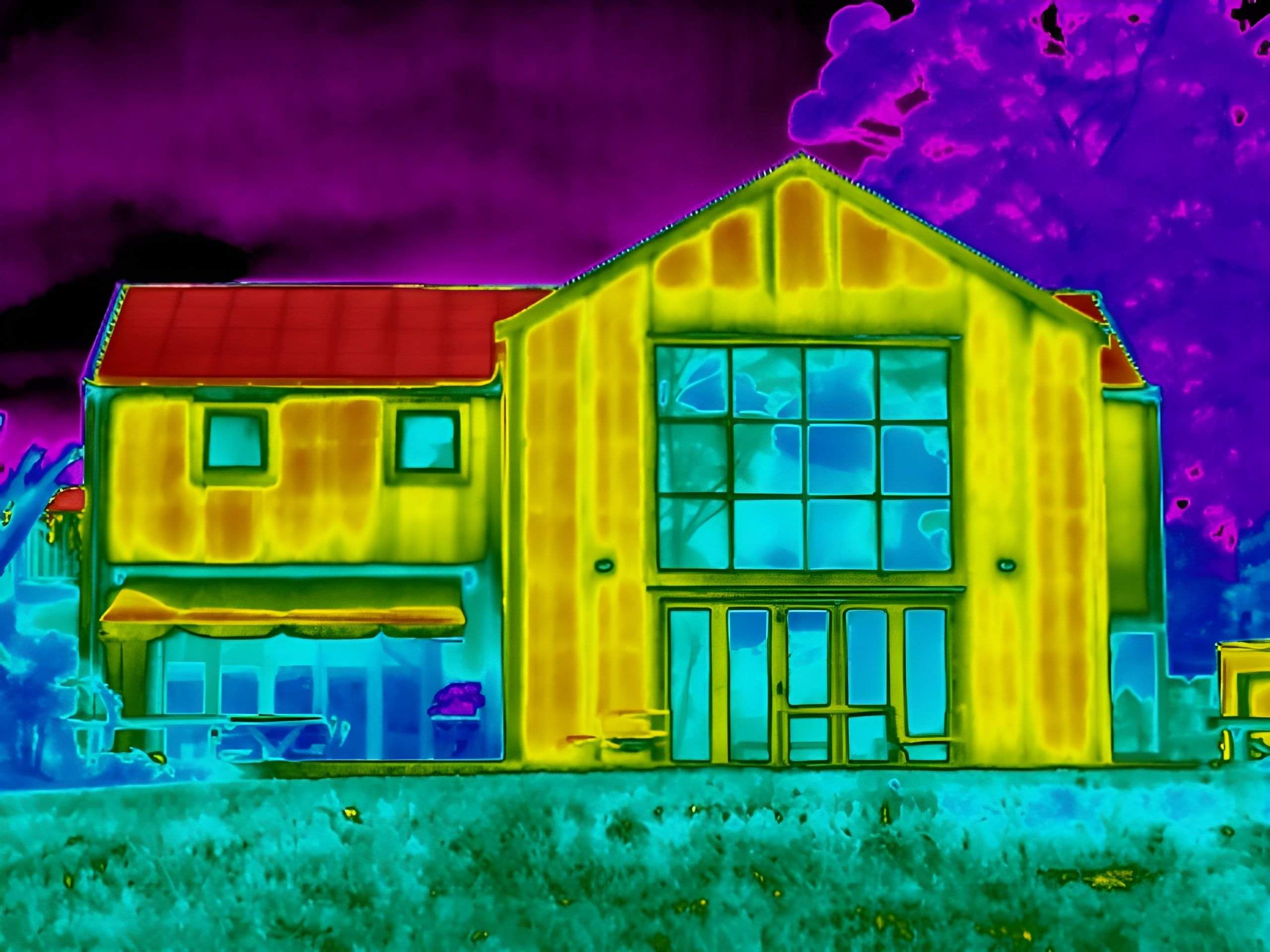

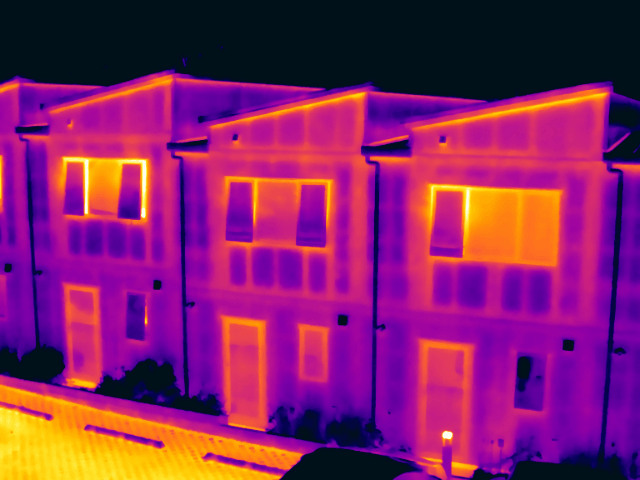

Building Thermography

Buildings can develop various issues due to poor construction, installation defects, material degradation, subsidence, extreme weather, and environmental factors. Our building thermal imaging inspections can be used in most building types to identify hidden issues and concentrate repairs where they are needed most.

Common issues we detect include:

Water ingress and leaks, trapped moisture, condensation, and air leaks

Poor heating/cooling energy efficiency

Missing or defective insulation

Cracks and voids in structural components

Delamination of composite materials, roofing, and facades

Electrical Periodic Verifications

Many insurance companies require businesses to carry out an electrical periodic verification in accordance with AS/NZS 3019:2007. This is a comprehensive inspection involving a detailed visual examination and limited or full testing of your electrical systems. We can conduct a periodic verification and prepare a detailed report with recommendations and a certificate of verification to meet your insurance requirements.

The Inspection Process

Step 1: We consult with you to determine the purpose, scope, and cost of the inspection. To ensure optimal results, we coordinate with you to schedule the inspection at a time when electrical and mechanical equipment is under load (operational). In most cases, our inspection will have no impact on your daily operations, allowing your business to continue as usual. For consistency and continuity, the same thermographer will always conduct your inspections.

Step 2: We evaluate the site conditions to identify potential access issues, risks, or hazards associated with the job, and prepare a detailed Job Safety Analysis (JSA). We will complete a site specific induction and permit to work if required.

Step 3: Our registered electrician/certified thermographer will safely carry out your inspection. Depending on the job, this may involve removing covers from electrical switchboards or guards from mechanical equipment to get a good view of the components. We exclusively use high resolution, calibrated, and accurate FLIR thermal imaging cameras.

Step 4: Once the inspection is complete, we ensure the site is left in a tidy and safe condition, and advise our site contact if we have found any faults or anomalies that require immediate attention.

Step 5: We load the images into our software for comprehensive analysis, and produce a clear and concise report containing thermal and visual images, object identification, fault classification, actionable recommendations, and all parameters relating to the inspection.